Documented proof performs a vital function within the FDA's process validation approach. The guidelines emphasize the necessity for complete documentation to display process Handle and make sure repeatability and reproducibility.

Revalidation is much more greatly utilized for clinical devices than drug merchandise. It is actually executed when prospective validation reaches a conclusion the production process is not able to produce the products constantly.

Regulatory companies not merely call for everyday living sciences firms to generate an item that satisfies its specifications but in addition need the processes, techniques, and functions executed during the producing of that products generate reproducible final results that satisfy stringent good quality requirements. This really is accomplished by means of validation.

Adequate sources must be allotted to be certain proper documentation and info integrity. Setting up a tradition of excellent and ongoing advancement is usually crucial for effective process validation.

Conference regulatory demands is paramount With regards to process validation. So that you can ensure the protection and efficacy of pharmaceutical merchandise, regulatory bodies including the FDA as well as the EMA have established guidelines that must be adopted. Let us check out these guidelines in more element:

Load extra contributions five Connect relevant documents and references The fifth segment of one's report must attach pertinent documents and references that complement your report. What are the regular operating methods, protocols, checklists, templates, or kinds that you just utilised or designed to the here process validation and verification pursuits?

This write-up examines five cleansing validation worries which can be removed by digitizing your cleansing validation approach with ValGenesis.

Exactly what are the design requirements and acceptance conditions? What exactly are the risks and assumptions concerned? How did you intend and execute the validation and verification checks? By answering these concerns, you may established the context and expectations for the rest of the report.

Master what QSR administration is, why it’s significant, and how to implement a QSR management strategy in your operations efficiently.

Process style should be based on stable evidence read more and include thorough documentation. Stakeholders have to record the experiments that have helped make improvements to their comprehension of the manufacturing processes.

Existing related quantitative and qualitative details gathered during the validation and verification process. Use Visible aids for instance graphs or tables to reinforce comprehension. Involve distinct proof like exam outcomes, statistical analyses, or stakeholder comments to guidance conclusions.

As you've in all probability guessed, pharmaceutical validation is sophisticated and jam packed with roadblocks and prospective pitfalls. Permit’s consider a more in-depth glimpse so we are able to be greater prepared for them:

The FDA's Process Validation Assistance delivers an extensive framework with the validation of pharmaceutical processes. It outlines a danger-based strategy that takes into account the possible effect on product or service quality and affected person security.

I've been tasked with serving to a client make a decision how to ascertain if incoming reused gear is "cleanse". Soon after hours of seeking relevant details your web site is the first time I have gotten some authentic help. Thanks.

Ariana Richards Then & Now!

Ariana Richards Then & Now! Michael C. Maronna Then & Now!

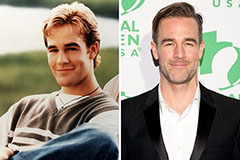

Michael C. Maronna Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!